| Sign In | Join Free | My chinacomputerparts.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My chinacomputerparts.com |

|

Brand Name : LiQi

Model Number : OEM

Certification : ISO,GE

Place of Origin : China

MOQ : Negotiable

Price : Negotiable

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 100000 Piece/Pieces per Month

Delivery Time : 35-50 days

Packaging Details : Wooden case

Product name : ABS Injection Mold

Mold life : 500000 shots

Design : Coat Hanger

Cavity : Multi

Runner System : Hot runner/ Cold runner

Surface treatment : Mirror Polish

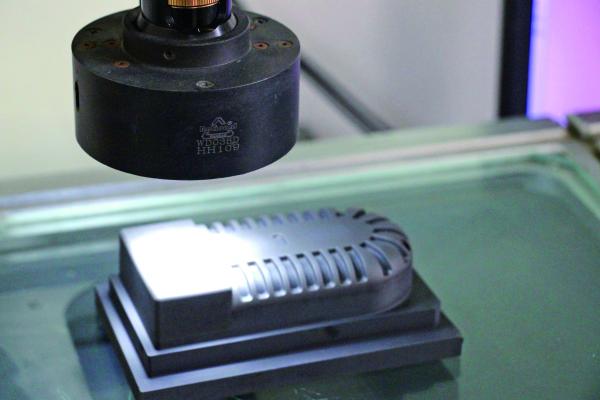

Self Development ABS Injection Mold Housing Cases For Gun Design

| Product Description | Self Development ABS Injection Mold Housing Cases For Gun Design |

| Plastic Materials: | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO,...etc. |

| Standard: | ISO9001:2008 |

| Other materials: | Rubber, Slilconce rubber, LSR,Aluminum, Zinc,Copper...Metal...etc. |

| Quality: | RoSH and SGS standard |

| Feature: | Non marking and Non flash |

| Size: | According to your 2D, 3D Drawing |

| Color,Quantity,Unit price,Tooling cost,Tooling size: | To be discussed |

| Package: | Standard exported Wooden box packed, Fumigation process(upon required) |

| Mold Building Lead Time: | T1, 4-5 weeks, Part measurement report (upon required). |

| Export Country: | Europe, Japan, America, Australian, UK, Canada, France, Germany, Italy...etc.: |

| Experience: | 13 years experience in plastic injection mold making and plastic prouducts produce. |

| To be discussed | In-Mold Decoration, Injection Mould, Plastic Mold, Overmould, 2K Mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold,Collapsible Core Mold, Die Sets, Compression Mold, Cold Runner System LSR Mold,...etc. |

| Mould Base: | Hasco Standard, European Standard, World Standard |

| Mould Base Material: | LKM, FUTA, HASCO, DME,...etc. Or as per Customer's Requirment. |

| Surface Finish: | Texture(MT standard), High gloss polishing |

| Cavity/Core Steel: | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 ...etc. |

| Hot/ Cold Runner | HUSKY, INCOE, YDDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand...etc. |

| Mould Life: | 5,000 to 1,000,000 Shots. (According to your working environment.) |

| Design & Program Softwares: | CAD, CAM, CAE, Pro-E, UG, Soild works, Moldflow, CATIA....etc. |

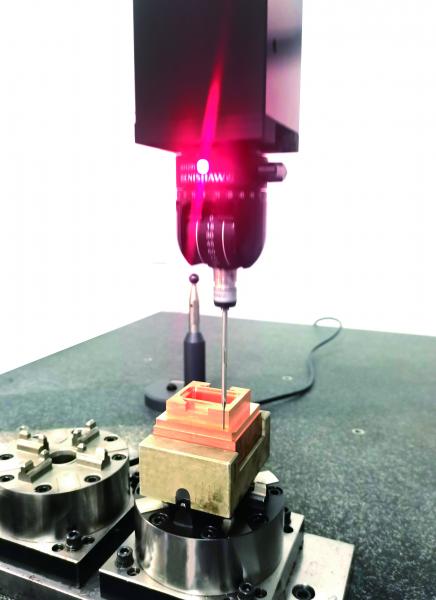

| Equipments: | High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine for trial out mold from 50-3000T available. |

ABS Injection Mold Pressure:

Because of ABS’s viscosity, higher injection pressures are needed than for many other materials, but lower pressures may still be suitable for smaller, simpler, or thicker products. Just bear in mind that if the injection pressure is too high, increased friction can cause molded parts to stick, which complicates their removal and adds to production costs. If the pressure is too low, mold shrinkage increases and can result in out-of-tolerance parts that won’t meet end-use requirements.

ABS Injection Mold Speed:

ABS Injection Mold speed is another important processing consideration. If the speed is too fast, ABS plastic may burn or thermally decompose. The results can include defects such as weld lines, poor glossiness, and discoloration. If the injection molding speed is too slow, however, there may be insufficient filling of the mold. For improved dimensional stability, the shot size that is required with ABS is less than with other plastics. This reduces material usage but still requires proper processing techniques.

FAQ

1. When can I get the price?

A: We usually quote within 24 hours after we get your inquiry.

2. How long is the lead time for mold?

A: It depends on the mold’s size and complexity. Normally, it nees about 25-35 days.

3. I don't have 3D drawing, how should I start the new project?

A: You can provide us a sample, we will make 3D drawing design.

4. Can we mass produce in your local?

A: Yes, you can leave the mould in our factory, we can produce for you.

5. Can we get a sample when mould finished?

A: Yes, we usually send out samples for customers' checking, then mass production after samples comfirmed.

6. Before shipment, how to make sure the products quality?

1) We have QC to inspect the products before each shipment.

2) We can send you videos to show the production process.

3) You can come to visit our factory or ask a third party for inspection.

7. How could I pay?

A: Paypal, Western Union, T/T are acceptable, so just let us know which is convenient for you.

8. How to ship?

A: By sea/ By air/ By Express.

|

|

RoSH SGS Injection Moulding Abs Plastic Housing Cases For Gun Design Images |